05 Dec Using Oxidation techniques to enhance your property interior

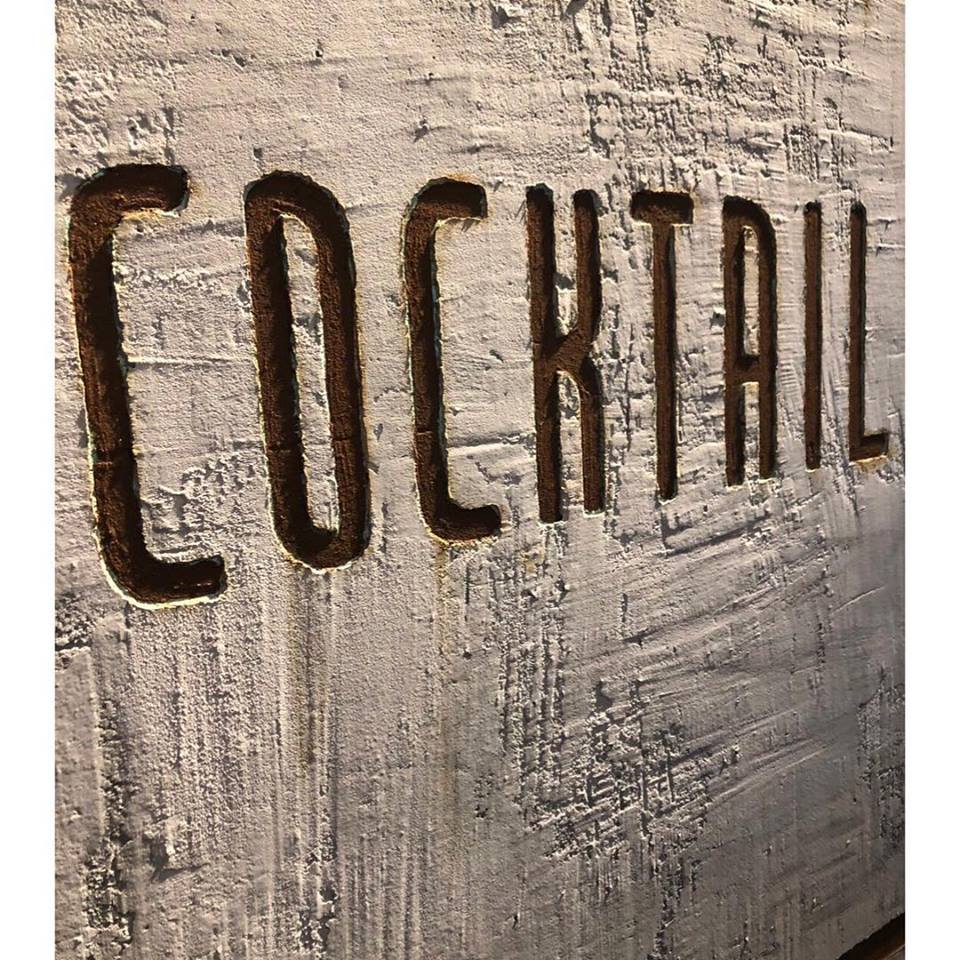

Did you know plaster can rust? By introducing metal particles such as steel or copper to a plaster mix and applying an activator once dry or wet, the metal particles rust, and the plaster turns into a seemingly solid metal surface. The finish is authentic and unique with each new application being different from the last.

‘Oxidation’ as it is called is an innovative and specialist plastering finish most plasterers won’t be familiar with. Introducing metal particles to plaster is contrary to the desired look a standard plastering achieves – a smooth, perfect surface. Oxidation introduces imperfection and texture to the finish which is all part of the charm.

Oxidation techniques are suitable for walls, ceilings and furnishings wherever a rustic, industrial look is desired. The finish itself feels grainy although not quite as rough as proper rust. The finish is also less susceptible to flaking.

Because different applications always achieve a slight variation in finish, you should use a specialist who understands how to achieve the result you require. The difference in finishes can be attributed to the type and number of metal particles in the plaster mix, and also how the plaster is applied and smoothed over if relevant.

Unlike wallpaper with a digitally printed rust, oxidised plaster is three dimensional and catches the light in unique ways. This makes it a much more interesting choice and certainly the more desirable option if your budget allows for it.

Rust

For rust to form on any metal, the metal must have some iron content. Metals that do not rust include gold, silver and platinum precisely because they do not contain iron. Another is stainless steel which contains the metals chromium and nickel.

However, metals without iron can ‘oxidise’. Copper, for example, doesn’t contain iron but does tarnish. Bronze also tarnishes.

Therefore to make use of oxidation techniques with plaster, we need to use metal particles that at the very least can tarnish. Any metal with iron content is a candidate, although we tend to use only a handful to achieve different results.

Copper

Copper doesn’t rust but it does corrode. The oxidation process results in a beautiful blue-green patina. Oxidation can be kickstarted with saltwater, heat or acidic compounds, with each of these resulting in a slightly different look. Copper is an important ingredient for any mix because it gives lasting durability to the finish.

Bronze

Like copper, bronze doesn’t rust but it does tarnish and corrode over time if exposed to elements. Bronze tarnish is always green-turquoise in colour, sometimes bright, sometimes dark, but always green-turquoise. The finish is beautiful and unique to each piece. It can consist of copper chlorides, sulphides, sulphates and carbonates.

Steel

Steel or iron particles do rust, unlike copper and bronze. The oxidation process results in a red or brownish patina which is what you will see underneath bridges. In this application, the corrosion is stable so stays red. If you used just steel in a plaster mix it would be a very deep red/ brown. A little copper is a good addition.

Creating different looks

As previously touched upon, the difference in oxidation plaster finishes can be attributed to the type and number of metal particles in the plaster mix, and also how the plaster is applied and smoothed over. Introducing saltwater to the mix will result in a different type of patina to form over introducing a chemical agent.

Time also plays a role in how oxidised plaster appears. Metals will continue to oxidise if unsealed, although the process becomes slower and slower indoors over time. Some walls turn red-brownish as the iron rusts first, before taking on a more interesting tone with hints of blue and green if there is copper content.

Most of the projects we work on contain a mix of metal particles. We commonly introduce steel and copper together to create a balance. Whatever the case, this decorative look is extremely contemporary and very popular, and we can usually match the patina to existing rusted or oxidised metalwork if you have it.

We can’t stress enough the importance of choosing a specialist who understands how to achieve the result you require. We are such specialists. Call us on 0772 548 8669 to discuss oxidation plastering techniques for your property.

No Comments